Precision Optics

ATE-Asia / ATE-Denmark has a long history of manufacturing some of the most demanding optics in the world.

ATE-Asia / ATE-Denmark has a long history of manufacturing some of the most demanding optics in the world.

Whether you need medico optic, spheric lenses for UV to IR application, light-weighted mirrors for a space-based application, or a lens system for image sensor equipment, we have the experience to meet your requirements.

- Optical lens: Singlet lens, Achromatic lens, Cylindrical lens, Aspherical mirror.

- Mirror: Metallic mirror, Dielectric mirror

- Optical Beamsplitter: Polarization Beamsplitter, Non-Polarization Beamsplitter

- Optical prism: Pentaprism, Dove prism, Corner cube retroflector, Right angle prism

- Optical Filters: Long / short Wave pass filter, Bandpass filter, ND filter, Color pass filter

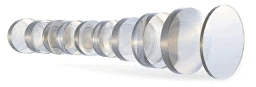

Lenses

Lenses have many applications in range from the simple collection of the scanning of laser beams to precise imaging and image transferring. Lenses are classified as singlet, achromatic cylindrical, and aspherical lens according to the different applications.

Selecting the proper lens for your application requires making a number of choices. Many considerations include: lens shape, conjugate ratio, f/number, transmission, wave front distortion, scattered light, anti-reflection coating, and cost. Base these, material is also an important factor for you to choose products. In ATE, the material of BK7, Fused silica, CaF2 and MgF2 as standard. Other materials are available upon requirement.

Manufacturing Capacity:

- Customized service to provide the sample and high volume production

- Products size from 0.8mm-350mm, Material from CDGM, SCHOTT, OHARA snd Crystal

- Month batch Production more than 500k pieces

- Coating: AR Coating, HR Coating, Filter Coating, Etc

- Inspect Machine

Our optical solutions

precision optics for professional use and with the right hardware

Optical prisms is based on the principles of optical reflection and refraction.

Optical prisms is based on the principles of optical reflection and refraction.

In order to change the direction of the image and the effect or light, the system is fed in a smaller space by the specific optical glass and it is designed as a geometry.

The production of optical prisms is based on planar grinding line, optical coating lines and optical glue lines. With the fixture precision and customized.

The specific information of optical prism are as follow:

Manufacturing Capacity:

● Customized service to provide the sample and high volume production

● Relying on optics design, can provide a prism assembly design and processing

● Provide coating design and optimization in free

● Optional optical extinction blackening requirements, environmental stability is good

● Month batch production is more than 100K pieces

● Product size from 2 mm – 100 mm, for optical glass materials

● Metrology:

Surface Accuracy: ZYGO Laser Interferometer

Angle Test: double tube Angle measuring instrument, measurement accuracy 1 ‘

Surface Quality: In vision and endoscope based on MIL-PRF-13830B, DIN3140-7 or GB1185-74 and B1185-74 standard

We design and manufacture a great choice of various high and partially reflecting mirrors for the spectral range: UV, Visible, Near Infrared Regions.

We design and manufacture a great choice of various high and partially reflecting mirrors for the spectral range: UV, Visible, Near Infrared Regions. Filters alter the characteristics of a beam of light either by changing the overall intensity of the beam without affecting its spectral content or by changing or separating the spectral content of the beam through wavelength-selective absorption or reflection.

Filters alter the characteristics of a beam of light either by changing the overall intensity of the beam without affecting its spectral content or by changing or separating the spectral content of the beam through wavelength-selective absorption or reflection. Beamsplitter is used to split or combine two perpendicular polarization laser beam.

Beamsplitter is used to split or combine two perpendicular polarization laser beam.